...Isolation Bushings are required for assembly.

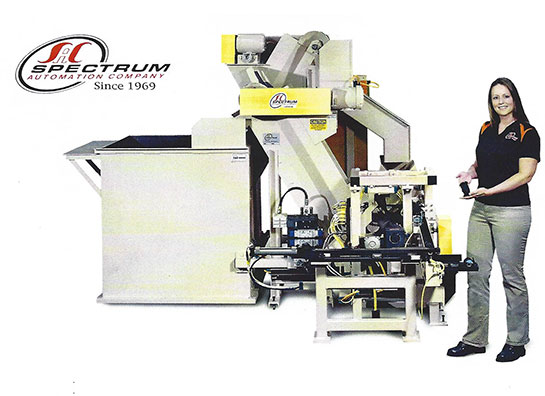

Twenty cubic feet of dry parts fills the storage bin. They are elevated into an orientor powered by a straightline vibratory drive.

Parts are live feed tracked, end to end into a pocket of an eight station horizontal axis carousel.

Parts are indexed to an inspection station to assure that a blue stripe is on either end.

Those with other colors are ejected at the next station.

Two stations immerse Bushings in oil. A drain-off station follows.

Parts are ejected toa live feed conveyor with oil collection features.

Inspected and oiled parts are escaped and held for ram assembly at nine pieces per minute.

Quiet, efficient and dripless.