They're Pumped!!

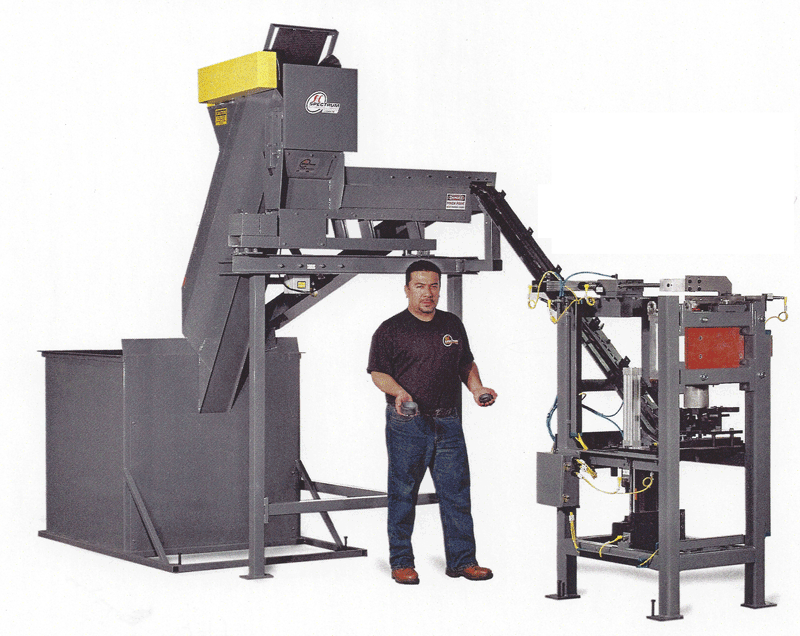

A family of twenty six RINGS (67 to 91mm O.D x 18 to 35mm thick) is fed, one size at a time, through an induction heater to a forge operation.

Here's how:

Twenty cubic feet of parts are stored, elevated, oriented, tracked, escaped and pumped up into a vertical axis induction heater. Each part "in" moves a hot part "out" which is shuttled to the forge at 10 seconds per cycle.

Tooling change is about 12 minutes.