Simulation Software Speeds Up Delivery Lead Times on Floorbin Elevator Vibratory Feed Systems

https://youtu.be/b7PVPfQfAII Since 1969, Spectrum Automation has manufactured custom parts feeding and material handling machines. We offer a full line of proprietary equipment used to move parts and components through manufacturing and assembly environments. Our engineers use state-of-the-art simulation software to test and debug custom designs before full-scale production, avoiding unforeseen costs and potential delays further […]

Robotic Assembly for Electric Vehicle Motors

Delicate magnet blanks are unloaded, weighed, distributed, and presented to robots for assembly into motors for electric vehicles. A robot places a tote of parts on Spectrum’s conveyor which moves and locates it for unloading. Totes hold five trays, each having 96 nested blanks. A gantry moves vacuum pick-up heads between the tray […]

Overhead Conveyance System

To work within a customer’s expedited timeline, these speciality conveyors were engineered and built in 40 days. These chassis weldments arrive on four overhead paths and range from 23” to 47” long. They are accumulated in batches on our short, rise-and-fall conveyor, then discharged onto a declining conveyor to a manual, fixture loading station. DOWNLOAD […]

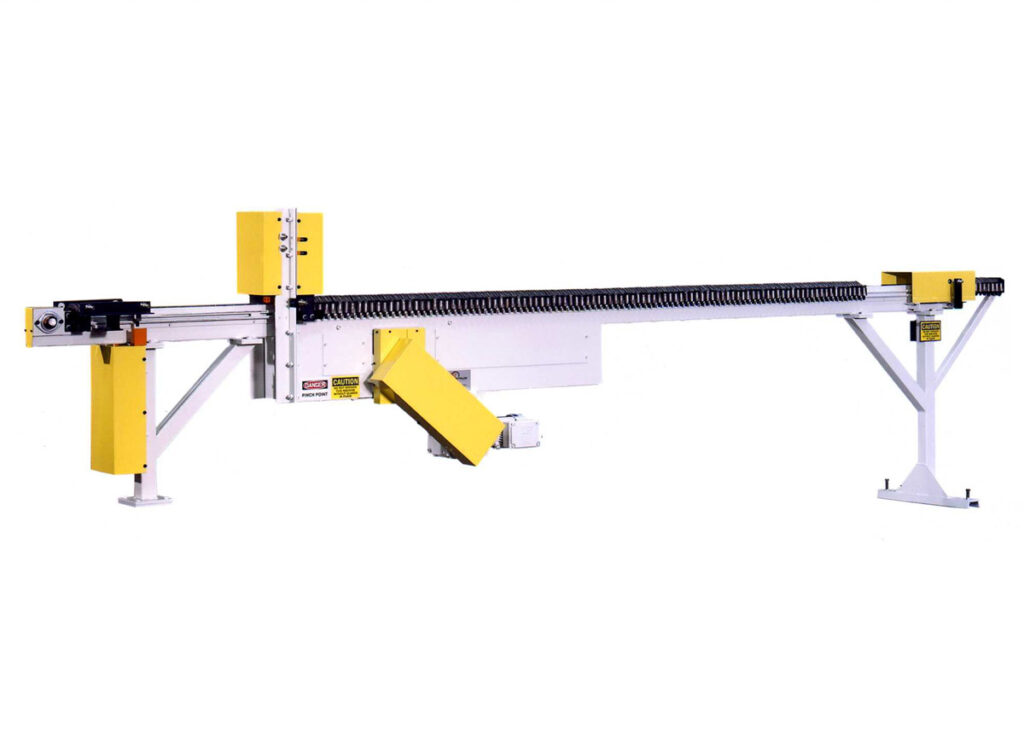

Custom Conveyor System

To work within a customer’s expedited timeline, these speciality conveyors were engineered and built in 40 days. These chassis weldments arrive on four overhead paths and range from 23” to 47” long. They are accumulated in batches on our short, rise-and-fall conveyor, then discharged onto a declining conveyor to a manual, fixture loading station. DOWNLOAD […]

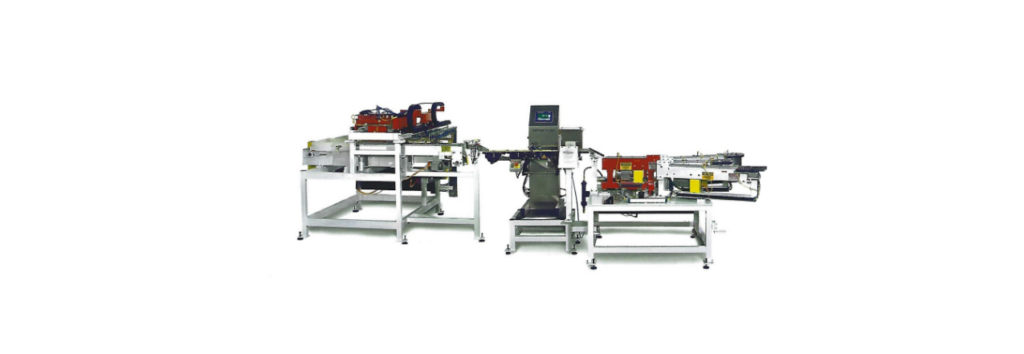

Dockable Parts Feeding System

Versatile features get valve guides and valve seats to O.D. grinders from batches stored in portable stock gondolas. The components are docked to an elevating conveyor and parts are chuted to an orienting conveyor. Guides are fed and flex tracked, end-to-end, to a vibratory live feed, exiting to the grinder rest blade at 190/240” per […]

Rotary Dumper Solves for Critical Floorspace Limits

In this system designed for a customer, sawn steel billets are fed to an induction heater at 15 – 35 pieces per minute, at an average noise of 85 dB(A). Parts are dumped from a stock box into a floorbin, then elevated to an orienting conveyor to exit, end-to-end, via a short track. Critical space […]

Custom Conveyor Stores 120 Parts

Spectrum Automation offers customized conveyance systems for a wide variety of industries and applications. In this custom conveyor designed for a customer, differential bearing caps, with bolts, are manually placed on the conveyor to protect the joint faces. It stores 120 parts in a face-to-face attitude for delivery to assembly. Caps are released and staged […]

VDL Linear Vibratory

There are four critical principles for maintaining the optimum operation of a vibratory unit: Isolation, Electrical Supply, Tightness, and Rigidity. Proper attention to these factors during maintenance and servicing ensures peak performance for parts feeding. For a vibratory unit to function at its best, certain fundamental principles must be adhered to. Proper operation depends on […]

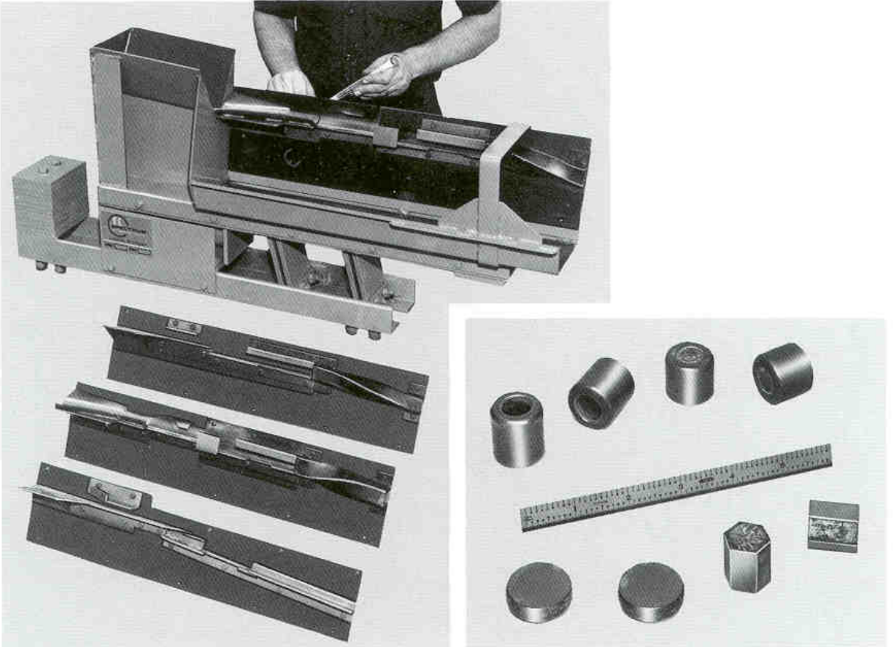

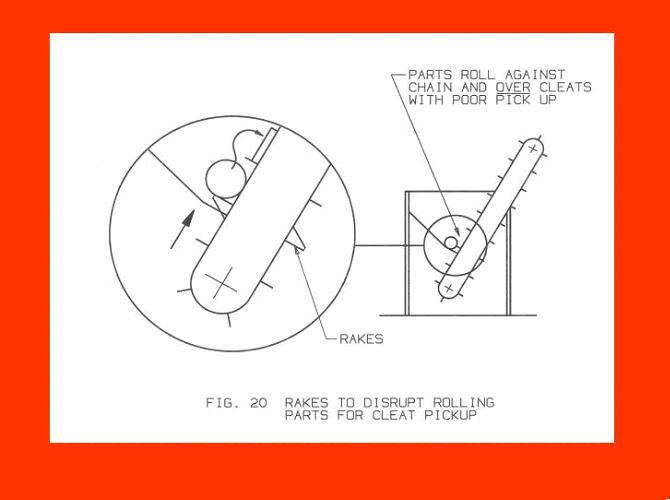

Parts Feeding For Cold Forming

In North America, over a hundred suppliers provide parts feeders, with around a dozen having been in the industry for over twenty years. While most focus on bowl feeder technology, several offer diverse feeder solutions to cater to specific needs. Despite its potential to improve profitability, feeder technology often receives less attention compared to other […]

Spectrum Automation Company’s Guide to Parts Feeding Machinery Concepts

We provide a comprehensive overview of various parts feeder concepts, leveraging over thirty years of experience to help you choose the best method for your needs. The optimal feeder choice depends on a detailed understanding of the parts to be fed, including their design, condition, and the environment they operate in. Essential information to gather […]