Parts Feeding

Over the last fifty years, numerous parts feeding techniques have enhanced automated production. Most current feeders are improved versions of early designs. Despite this, comprehensive sources on parts feeder technology are limited, making it crucial for users to stay informed about advancements. Updates should be tailored to specific project needs and reviewed by experts. Experienced […]

Stepper System Automates E-Clip Assembly

To reliably automate the assembly of E-Clips for a customer, the Spectrum Automation team tooled this Mini-Feeder to get them to a robot. Parts are stored in a half-cubic-foot bin and step-metered to a linear vibratory orientor. A static mandrel gets oriented parts into a vertical stack where a coinchanger escapement moves one at a […]

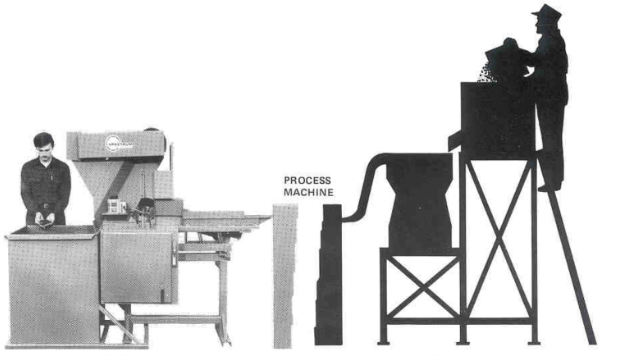

Coinchanger System Feeds Automatic Assembly

In this customized system, coinchanger features are used to gently feed parts to automatic assembly. Stack tubes store, meter, and present bearings, bushings, seals, gears, and similar shaped parts for auto pick-off. Quickly filled vertical tubs are manually loaded with a four-hour supply of bearings from or in cardboard tubes. One part at a time […]

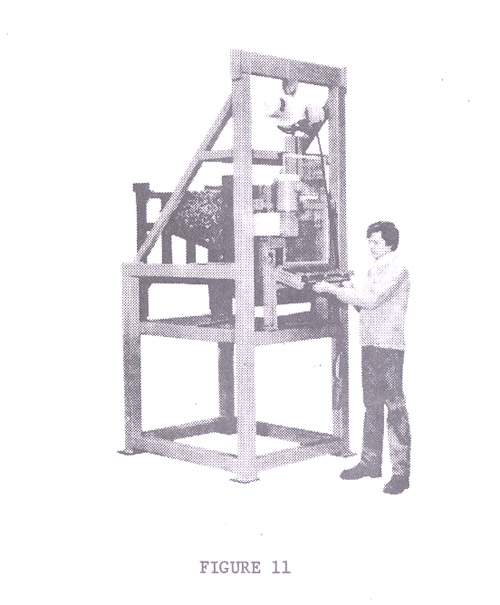

Dial Indexer System

In this custom dial index application, flex plate bolts were bulk stored, elevated, vibratorally oriented, live fed and escaped to a pick-and-place unit. A rotary indexer, with a 7-position bolt tooling plate, is loaded by the pick-and-place every 20 seconds. A robot picks up the seven parts and transfers them to assembly. Similar flywheel bolts […]

Vibratory Parts Feeder Bowl v. Straight Line: A Comparison

You can choose either mechanical or vibratory driven parts feeders to suit your needs. Mechanically operated units have been around the longest, but they never earned the great popularity enjoyed by jam forging vibratory driven feeders. Many believe that all vibratory parts orienting is done with the familiar bolt feeder. When overwhelmed by bowl feeder […]