In North America, over a hundred suppliers provide parts feeders, with around a dozen having been in the industry for over twenty years. While most focus on bowl feeder technology, several offer diverse feeder solutions to cater to specific needs. Despite its potential to improve profitability, feeder technology often receives less attention compared to other cold forming components. This presentation aims to highlight the importance of making informed feeder choices to enhance productivity.

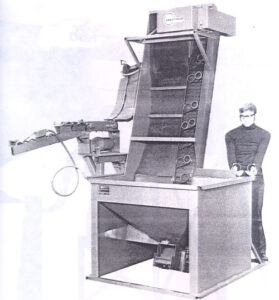

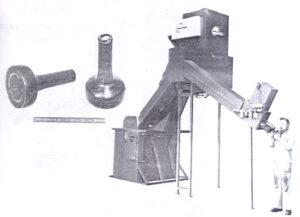

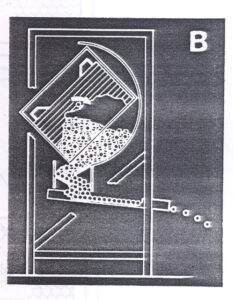

Floorbin Elevator – Gravity Orienting

Gravity orienting floorbin elevators are effective for feeding simple rolling and sliding parts, providing low-cost storage and easy access. They can handle a range of parts with minor adjustments, but complex shapes may require additional, costly features. Such systems are not easily adaptable to new part shapes and are prone to performance issues with tramp materials and heavy lubricants.

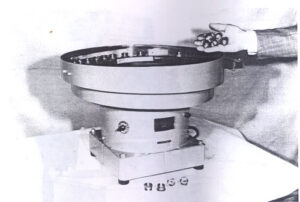

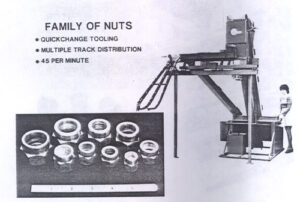

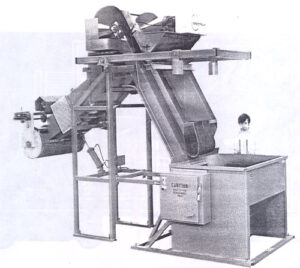

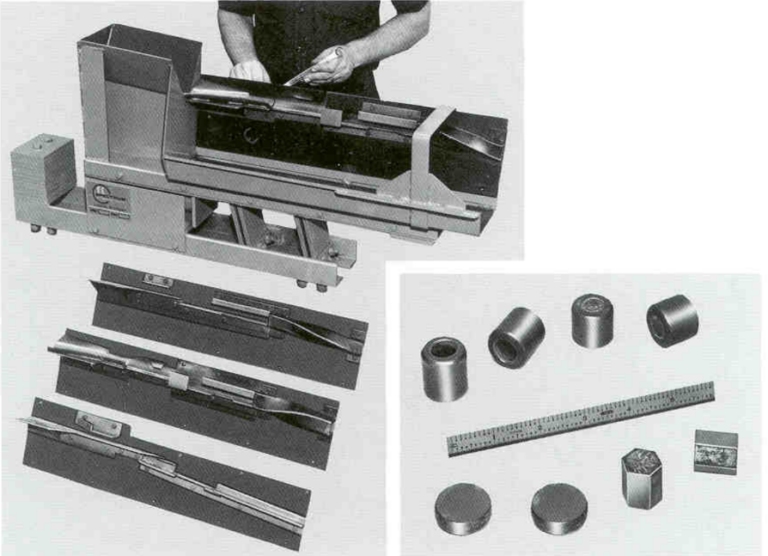

Vibratory Orientor – Bowl

Vibratory bowl feeders are popular and economical for small part shapes, available in various sizes. They often require additional backup hoppers to meet storage needs and can cause parts and tooling wear, noise, and lubricant loss due to the constant vibration of parts. These feeders are typically less adaptable to part changes without significant adjustments or multiple units.

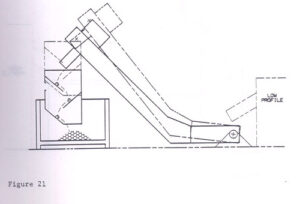

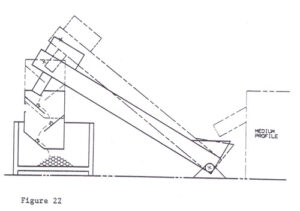

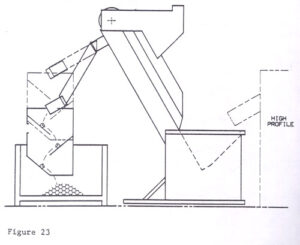

Vibratory Orientor – Straightline

Straightline vibratory orientors, a newer concept, utilize straight paths for parts orientation and often require a combination with floorbin elevators. These orientors are less noisy, cause less parts abuse, and have longer lifespans compared to bowl feeders. They feature bolt-in tooling for quick changeovers and can handle complex tasks with additional tooling.

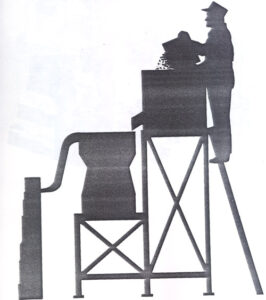

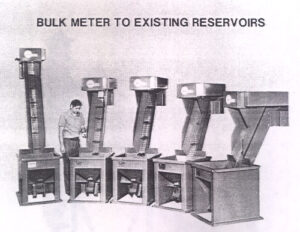

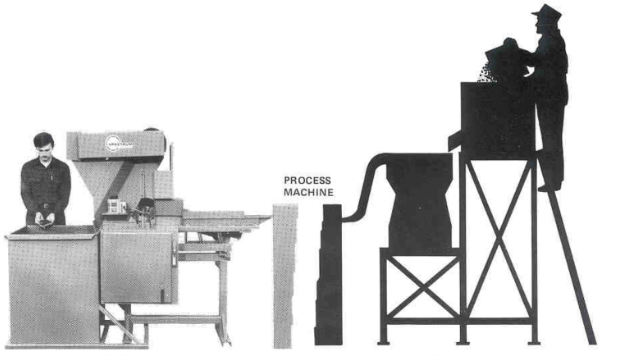

Floorbin Elevator – Bulk Feed

Non-orienting bulk feeding systems are used for processes like lube coating, washing, and heat treating. These systems can accurately release batches of parts based on weight or continuous feed rates, maintaining product quality while meeting process requirements.

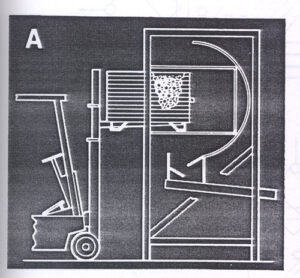

Gondola Dumper

Standard hydraulic or rotary cradle gondola dumpers are used to gently remove products from stock containers. The rotary cradle design minimizes safety concerns and allows complete evacuation of contents. Advanced features like fixed fenders enable controlled dumping, ideal for handling fragile parts.

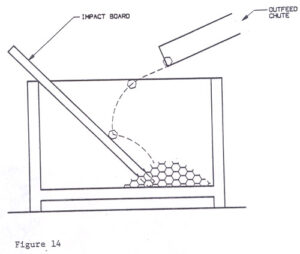

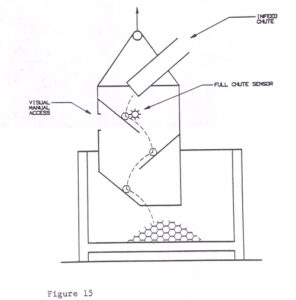

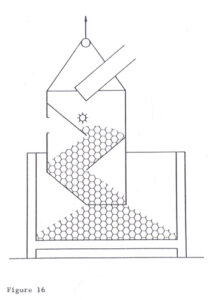

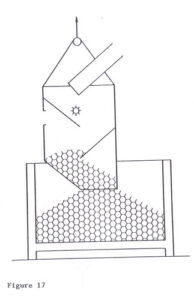

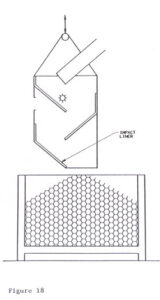

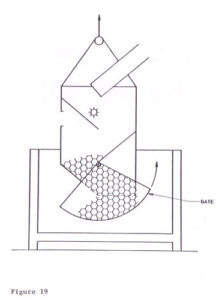

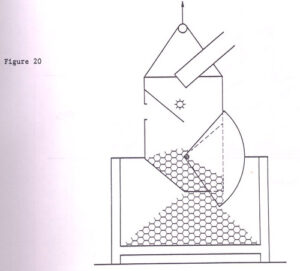

Gondola – Gentle Fill

A new concept for gentle filling of stock boxes uses a vertical, baffled down-chute to control the free-fall path of parts, minimizing damage. The down-chute can be adjusted automatically or manually to accommodate various part sizes and fill levels, ensuring gentle handling and quality preservation.

Summary

Cold-formed parts manufacturers should leverage the expertise of experienced parts feeder sources to achieve optimal parts handling and productivity improvements. These specialists continuously update their knowledge and provide valuable insights for better parts feeder solutions.

Figures:

- Fig. 1: Gravity orienting floorbin elevators for simple rolling and sliding parts.

- Fig. 2: Vibratory bowl feeder for small complex parts.

- Fig. 3: Components of a bowl feeder station.

- Fig. 4: Typical floorbin elevators for bowl feeder stock supply.

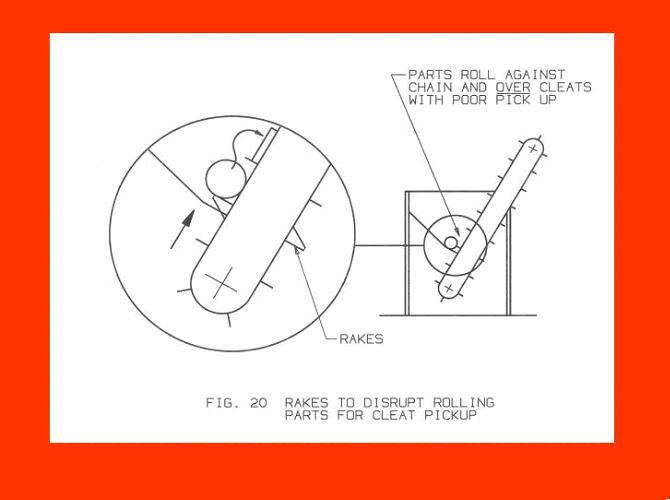

- Fig. 5-23: Various feeder setups, including straightline vibratory drives and down-chute systems, highlighting different parts feeding and handling applications.