Delicate magnet blanks are unloaded, weighed, distributed, and presented to robots for assembly into motors for electric vehicles.

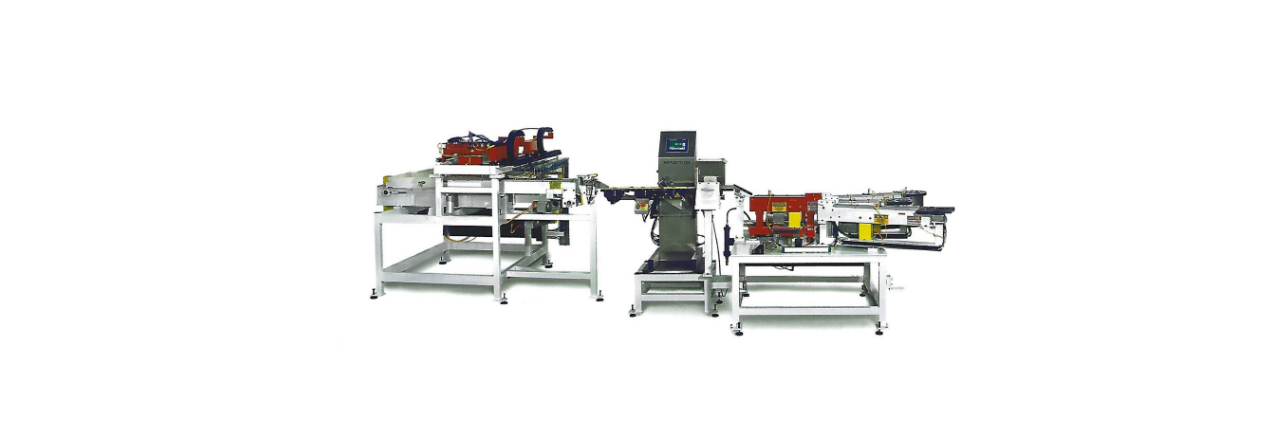

A robot places a tote of parts on Spectrum’s conveyor which moves and locates it for unloading. Totes hold five trays, each having 96 nested blanks.

A gantry moves vacuum pick-up heads between the tray and a dual path take-away conveyor. When a tray is emptied, the gantry action uses a vacuum pick to move the tray to an adjacent empty tote. When an empty tray remains in a tote, it is shuttled to the adjacent exit conveyor and held to receive four more emptied trays. The tote is then conveyed back to the robot.

The discharge conveyor feeds 108 pieces per minute via dual paths to a merge device. Parts are released to a conveyor for on-the-fly weight inspection. Parts exceeding +/- 2 gram tolerance are ejected.

Pieces move to a distribution conveyor which pivots to get the pieces to three final conveyors. Presentation escapements get the pieces to three robots which pick and place them into rotor assemblies.