There are four critical principles for maintaining the optimum operation of a vibratory unit: Isolation, Electrical Supply, Tightness, and Rigidity. Proper attention to these factors during maintenance and servicing ensures peak performance for parts feeding. For a vibratory unit to function at its best, certain fundamental principles must be adhered to. Proper operation depends on isolation from external influences, reliable electrical supply, tightness of components, and structural rigidity. Ensuring these aspects are correctly managed will keep the machine in good working order.

1. Isolation

Vibratory units must be isolated from associated tracks and chutes to prevent contact that can disrupt operation. Electrical drops, air, or hydraulic lines should not touch the unit to avoid damaging the drive. Safety brackets should not be tightened down on the unit; only neoprene feet should contact the external environment. These feet must remain undamaged, and there should be no end contact with bolts inside the feet.

2. Electrical Supply

A consistent 115-volt power supply must be available through the drive unit speed controller, ensuring the internal motor coil components function correctly. Poor drive performance often indicates a faulty diode within the electrical shroud, which should be checked and replaced if necessary.

3. Tightness

Interchangeable and adjustable tooling can lead to loose or missing bolts, which detune and harm the unit. Ensure all fasteners are secured with lock washers, Loctite, or both, and torqued to their design maximum. Spring pack bolts and counterweight bolts must be torqued to 75 foot-pounds using a 1/2 inch flex bar and socket.

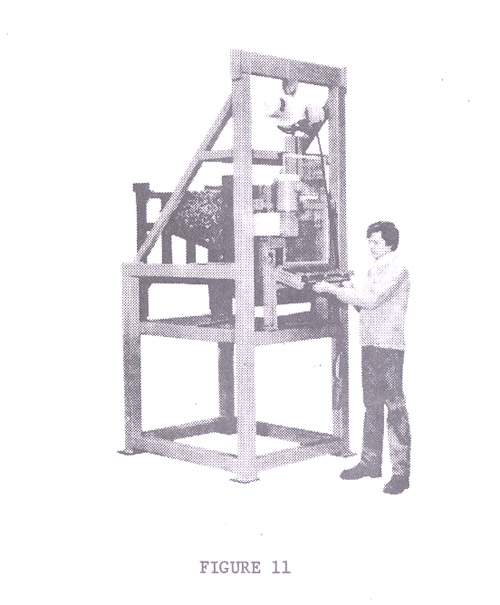

4. Rigidity

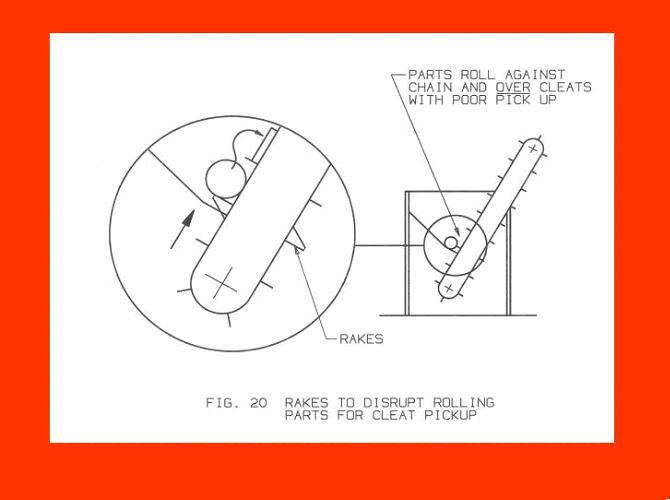

Proper rigidity means no orientor tooling should deflect more than 1/32 inch under thumb pressure (approximately 20 pounds of force). Violations in isolation and tightness will result in insufficient rigidity, compromising unit function. The structure supporting the drive unit must be rigid, as a weak support will move instead of the tooling. Signs of wear, such as mushrooming of tooling from continuous pounding, indicate potential cracks. Inspect for cracks around holes, spring anchor welds, and the counterweight base, especially if external contacts are suspected. Clean the unit and use a flashlight for thorough inspection.

Maintenance and Servicing

Regular inspections and maintenance are crucial. Check for cracked springs by dropping them from waist height onto a concrete floor; a clear ring indicates sound springs, while a dull thud indicates cracks. Inspect the unit, especially around welds and the counterweight base, for any signs of structural damage. Clean units thoroughly before inspection.

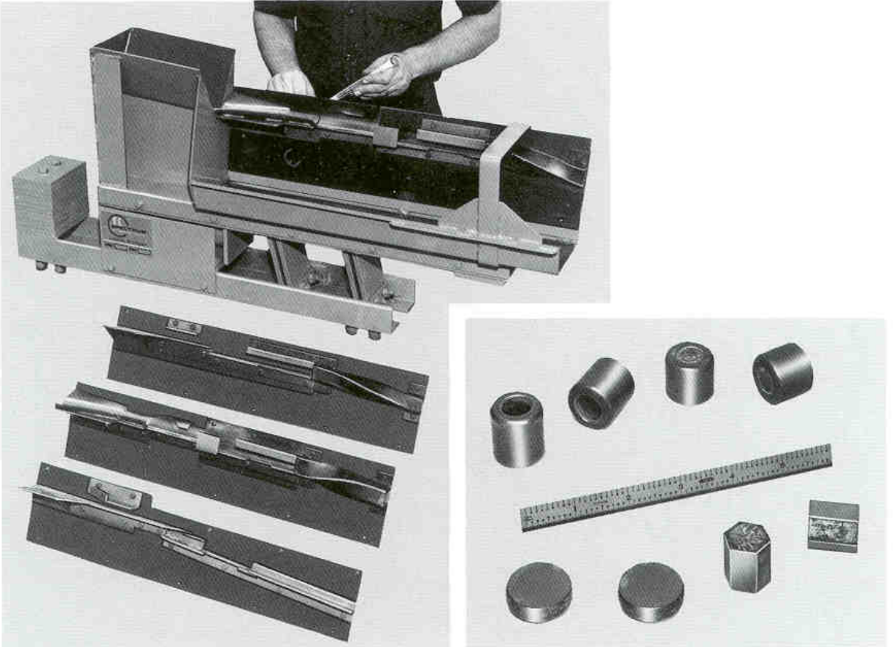

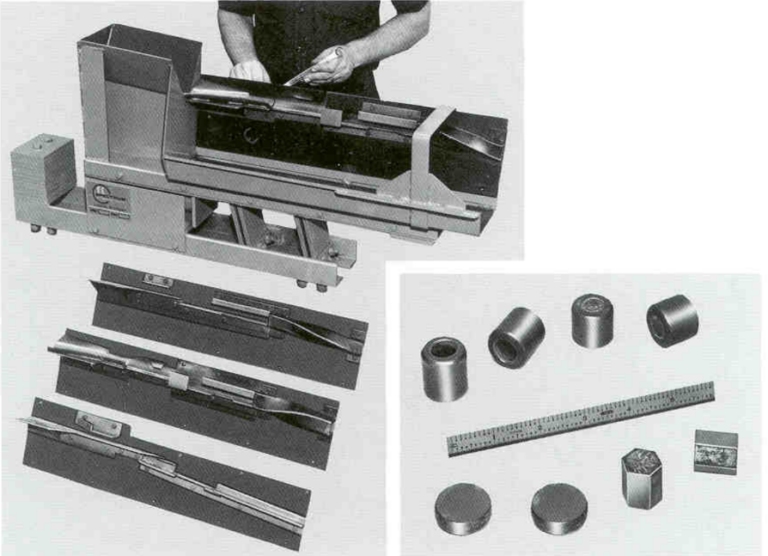

Tooling and Tuning

All tooling will eventually wear out and need replacement. Since each unit is tuned before shipment, any significant weight changes in tooling may require retuning. Heavier materials won’t increase endurance unless the unit is retuned accordingly. For significant changes, consult with a Spectrum serviceman. Ensuring the unit adheres to the principles of isolation, electrical soundness, tightness, and rigidity guarantees optimal performance.

Conclusion

By focusing on the four principles of Isolation, Electrical Supply, Tightness, and Rigidity, you can maintain your vibratory unit at peak performance. Regular inspection and proper maintenance aligned with these principles will ensure the longevity and efficiency of the unit.